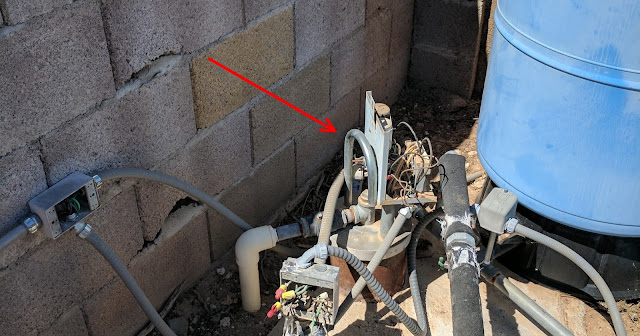

Now, I'm going to talk about the plumbing on the well. Let's start off with something that was simply annoying. Every well needs a vent; you have to let some air in when you take the water out. Around here, it's a simple curved pipe with a screen on the end of it that screws into the well head. Here's a picture of the one that used to be on my well:

To get it off and have access to pour disinfectant into the well, I had to unscrew this thing. Notice what happens when you turn it counter clockwise to remove it? Yes, it slams into the well controller and won't go any further. I could remove the well controller and run the risk of losing the bottom pump wiring down the well, or cut the darn vent pipe. I went and got the reciprocating saw and cut it in half. Terrible waste of a $20 piece of specialized pipe, but I wasn't willing to pull the controller.

When I replaced it I just used some PVC pipe shaped into an inverted 'J' with a hose screen stuffed into the end.

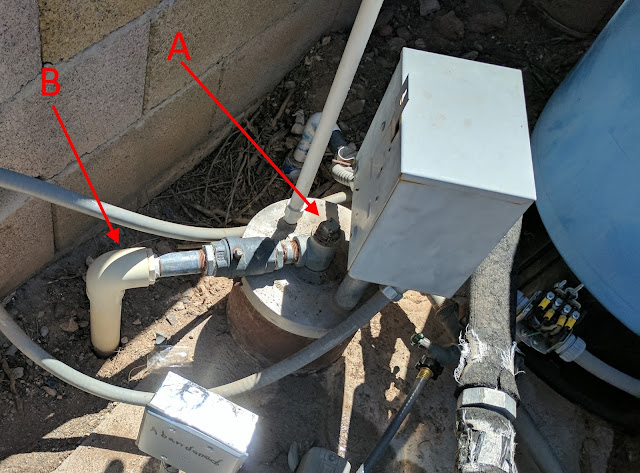

Notice I made it plenty long enough to get off, I also put threaded fittings in the middle so I can unscrew the top and stick in a funnel for pouring disinfectant down the well. I wanted to put a faucet on the well head as well so I could pump disinfectant in a circle through the well and the perfect place to put it was to remove the pipe plug at the location labeled 'A' in the picture below:

But, of course, the pipe plug had merged at the atomic level with the tee fitting below it. I had a 36 inch pipe wrench in there and couldn't get it to budge. The problem with a wrench that large is the risk of actually breaking a pipe. I really, really didn't want to break a pipe, so I opted to change out the fitting at location B with a tee and put the faucet there. It worked out pretty nicely:

I used a union to connect the new fittings to the old pipe because you never know when you might have to service something here and I didn't want to have to dig it out at some really inconvenient time. Also, it's too tempting for someone that wants to hook up to the water to use that faucet for a hose which will let air into the system when the bottom pump isn't on. Also, if there isn't any water there because the bottom pump isn't on, they might start messing with stuff to get water. I really didn't want that, so I replaced the faucet with a piece of pipe for day to day use. If I want to use the faucet, I just unscrew the pipe and put the faucet in place.

Those two items were done now, so I turned the system on and immediately ran into problems. The pump was cavitating which means that it was sucking air somewhere. I tried the trick of Saran Wrap around the various fittings to try and find the leak and couldn't; it must be sucking air somewhere. Maybe the underground pipe got messed up somehow.

I went and got a shovel and started digging along the pipe that leads from the well head to the tank and found this:

Well, not exactly this. It wasn't cut and plugged when I found it. Someone had taken the easy way out again and just used a tee to connect to the bottom tank pipe to get the water from the well into the tank. That meant that the surface pump would suck from the well anytime the well pump happened to be on at the same time. That presents problems because it could suck air from the well, not the tank. It would also mean that the water from the well wouldn't have time to settle and sand could be shoved out the lines to the houses plugging things up.

Not only that, notice the concrete around the base of the elbow fitting? The pipes had been put in before the wall was built and they had covered the pipes with concrete. Since there was no 110 VAC at the well, I couldn't use my jack hammer, so I used a hammer and chisel to break up the concrete to expose enough of the fittings to work with. This picture is after I had removed the concrete and separated the line to the bottom of the tank from the well head.

Remember, this is our source of water and the surface jet pump was cavitating this whole time. I didn't stop to take pictures of the mess at first. After I plugged the tee fitting off, the surface pump forced the air out of the house line and stopped having trouble. The houses had water, albeit only as much as was in the tank since the open pipe led to the well. I was stuck finishing the job to get us back in service; no time to throw a fit and storm around. that would have to wait 'til later.

In retrospect, I should have realized there was a problem here. There was no pipe going into the holding tank at the top fitting. Remember this picture from a previous post:

It pretty obvious that there should have been a pipe going into the tank right where the white pipe plug is. There's even a pipe to direct the water down into the well.

I started digging a trench over to the well and kept hitting the pipe that led to the bottom of the tank, so it was a shallow trench. I don't feel a bit guilty about only digging a shallow trench; I was fighting what was already there. I got the trench in and installed a couple of 45 degree fittings:

Then I completed the water run over the existing tank top fitting to get the well head connected to the tank where it should have been for the last many years.

I turned on the well pump (actually, I twisted a couple of wires together) and gritted my teeth just in case, but it worked fine. The water came up, went through the new pipe, and filled the tank. Everything was working again and water was restored. This time a bit more correctly than it had been in years.

Now, there was time to throw a fit and storm around. I took out my frustration of someone screwing up this simple step and covering it with concrete on the loose dirt as I put it back in the trench. It raised quite the dust cloud.

Notice that the ground is dry? After the first day of dealing with a muddy mess, I realized that hooking a water hose to the system allowed me to run the water without having it puddle up right where I was working. I could also stick the hose in the top of the well and save the water. I never had problems with leaks in the various pipes, I may have finally gained enough skill to join pipes correctly the first time, or maybe I just got lucky.

Probably should put some stepping stones over the barely covered pipes though.

End of part 4.

To get it off and have access to pour disinfectant into the well, I had to unscrew this thing. Notice what happens when you turn it counter clockwise to remove it? Yes, it slams into the well controller and won't go any further. I could remove the well controller and run the risk of losing the bottom pump wiring down the well, or cut the darn vent pipe. I went and got the reciprocating saw and cut it in half. Terrible waste of a $20 piece of specialized pipe, but I wasn't willing to pull the controller.

When I replaced it I just used some PVC pipe shaped into an inverted 'J' with a hose screen stuffed into the end.

Notice I made it plenty long enough to get off, I also put threaded fittings in the middle so I can unscrew the top and stick in a funnel for pouring disinfectant down the well. I wanted to put a faucet on the well head as well so I could pump disinfectant in a circle through the well and the perfect place to put it was to remove the pipe plug at the location labeled 'A' in the picture below:

But, of course, the pipe plug had merged at the atomic level with the tee fitting below it. I had a 36 inch pipe wrench in there and couldn't get it to budge. The problem with a wrench that large is the risk of actually breaking a pipe. I really, really didn't want to break a pipe, so I opted to change out the fitting at location B with a tee and put the faucet there. It worked out pretty nicely:

I used a union to connect the new fittings to the old pipe because you never know when you might have to service something here and I didn't want to have to dig it out at some really inconvenient time. Also, it's too tempting for someone that wants to hook up to the water to use that faucet for a hose which will let air into the system when the bottom pump isn't on. Also, if there isn't any water there because the bottom pump isn't on, they might start messing with stuff to get water. I really didn't want that, so I replaced the faucet with a piece of pipe for day to day use. If I want to use the faucet, I just unscrew the pipe and put the faucet in place.

Those two items were done now, so I turned the system on and immediately ran into problems. The pump was cavitating which means that it was sucking air somewhere. I tried the trick of Saran Wrap around the various fittings to try and find the leak and couldn't; it must be sucking air somewhere. Maybe the underground pipe got messed up somehow.

I went and got a shovel and started digging along the pipe that leads from the well head to the tank and found this:

Well, not exactly this. It wasn't cut and plugged when I found it. Someone had taken the easy way out again and just used a tee to connect to the bottom tank pipe to get the water from the well into the tank. That meant that the surface pump would suck from the well anytime the well pump happened to be on at the same time. That presents problems because it could suck air from the well, not the tank. It would also mean that the water from the well wouldn't have time to settle and sand could be shoved out the lines to the houses plugging things up.

Not only that, notice the concrete around the base of the elbow fitting? The pipes had been put in before the wall was built and they had covered the pipes with concrete. Since there was no 110 VAC at the well, I couldn't use my jack hammer, so I used a hammer and chisel to break up the concrete to expose enough of the fittings to work with. This picture is after I had removed the concrete and separated the line to the bottom of the tank from the well head.

Remember, this is our source of water and the surface jet pump was cavitating this whole time. I didn't stop to take pictures of the mess at first. After I plugged the tee fitting off, the surface pump forced the air out of the house line and stopped having trouble. The houses had water, albeit only as much as was in the tank since the open pipe led to the well. I was stuck finishing the job to get us back in service; no time to throw a fit and storm around. that would have to wait 'til later.

In retrospect, I should have realized there was a problem here. There was no pipe going into the holding tank at the top fitting. Remember this picture from a previous post:

It pretty obvious that there should have been a pipe going into the tank right where the white pipe plug is. There's even a pipe to direct the water down into the well.

I started digging a trench over to the well and kept hitting the pipe that led to the bottom of the tank, so it was a shallow trench. I don't feel a bit guilty about only digging a shallow trench; I was fighting what was already there. I got the trench in and installed a couple of 45 degree fittings:

Then I completed the water run over the existing tank top fitting to get the well head connected to the tank where it should have been for the last many years.

I turned on the well pump (actually, I twisted a couple of wires together) and gritted my teeth just in case, but it worked fine. The water came up, went through the new pipe, and filled the tank. Everything was working again and water was restored. This time a bit more correctly than it had been in years.

Now, there was time to throw a fit and storm around. I took out my frustration of someone screwing up this simple step and covering it with concrete on the loose dirt as I put it back in the trench. It raised quite the dust cloud.

Notice that the ground is dry? After the first day of dealing with a muddy mess, I realized that hooking a water hose to the system allowed me to run the water without having it puddle up right where I was working. I could also stick the hose in the top of the well and save the water. I never had problems with leaks in the various pipes, I may have finally gained enough skill to join pipes correctly the first time, or maybe I just got lucky.

Probably should put some stepping stones over the barely covered pipes though.

End of part 4.